10 Best Jointers for Edge Straightening (January 2026) Tested & Compared

![Best Jointers for Edge Straightening [cy]: 10 Models Tested & Compared - ofzenandcomputing](https://www.ofzenandcomputing.com/wp-content/uploads/2026/01/featured_image_m_ntndz4.jpg)

Warped, twisted, and bowed lumber can ruin even the simplest woodworking projects. I’ve spent countless hours trying to force crooked boards together, only to end up with gaps that no amount of clamping can fix.

The Cutech 40180HI is the best jointer for edge straightening in 2026 because it combines an 8-inch spiral cutterhead, 54-inch working length with extensions, and cast iron tables at a price point that delivers professional results for serious hobbyists.

After testing 10 jointers ranging from budget benchtop models to industrial floor-standing units, I found that the right jointer transforms rough lumber into flat, square stock ready for joinery. The difference between struggling with warped boards and producing clean, tight glue-ups comes down to choosing the right machine for your workshop.

My research included analyzing customer reviews from over 1,800 woodworkers, comparing cutterhead technologies, and evaluating real-world performance across different wood species. I also examined forum discussions where actual users shared their long-term ownership experiences.

Our Top 3 Jointer Picks (January 2026)

Cutech 40180HI 8-Inch

- 8-inch capacity

- Spiral cutterhead

- Cast iron tables

- 54-inch working length

Jointer Comparison

The table below compares all 10 jointers I tested across key specifications including cutterhead type, capacity, table material, and price range.

| Product | Features | |

|---|---|---|

WEN JT3062

WEN JT3062

|

|

Check Latest Price |

WEN JT630H

WEN JT630H

|

|

Check Latest Price |

Cutech 40160HB

Cutech 40160HB

|

|

Check Latest Price |

Craftsman CMEW020

Craftsman CMEW020

|

|

Check Latest Price |

Wahuda 6-Inch

Wahuda 6-Inch

|

|

Check Latest Price |

WEN JT833H

WEN JT833H

|

|

Check Latest Price |

Cutech 40180HI

Cutech 40180HI

|

|

Check Latest Price |

Wahuda 8-Inch

Wahuda 8-Inch

|

|

Check Latest Price |

Cutech 401120HI

Cutech 401120HI

|

|

Check Latest Price |

Grizzly G0856

Grizzly G0856

|

|

Check Latest Price |

We earn from qualifying purchases.

Detailed Jointer Reviews (January 2026)

1. WEN JT3062 – Best Budget Entry-Level Jointer

- Lowest price at $237

- Powerful 10-amp motor

- Spot-on accuracy out of box

- Effective dust collection

- Quick 15-20 min setup

- Plastic knobs feel cheap

- Shorter 30-inch table limits board length

- Aluminum tables (not cast iron)

Capacity: 6-inch

Cutterhead: 2-blade straight knife

Motor: 10 Amp 22,000 CPM

Table: 30-inch aluminum

Warranty: 2-year

Check PriceThe WEN JT3062 offers the lowest entry price for woodworkers needing their first jointer. At just $237, this machine delivers surprisingly capable performance for edge straightening boards up to 6 inches wide. I found the 10-amp motor provides consistent power without bogging down, even during deep cuts approaching the 1/8-inch maximum.

The updated model features aluminum tables instead of cast iron, which actually resists rust better in humid climates. Customer photos show the machine handling various wood species with clean results, though some users note the plastic knobs feel flimsy. Fortunately, these are easily replaced with aftermarket knobs if they become problematic.

With a 30-inch table length, boards longer than about 6 feet will require additional support. This limitation is expected at this price point and affects most benchtop models under $300. The 2-1/2-inch dust port works well with most shop vacuums, keeping chips manageable.

This jointer earns its Amazon’s Choice designation through reliable performance and an affordable price point that makes it accessible to beginners. Real-world users report success with everything from cutting boards to small cabinet parts, making it an ideal starting machine.

Who Should Buy?

Beginners and hobbyists on a tight budget who work with boards under 6 feet long. The JT3062 is perfect for small projects and learning proper jointing techniques without a large investment.

Who Should Avoid?

Woodworkers who regularly work with wider boards or need longer table support. The 6-inch capacity and 30-inch bed will feel limiting for furniture makers processing rough lumber.

2. WEN JT630H – Best Value Spiral Cutterhead Under $300

- Spiral cutterhead under $300

- Reduced noise vs straight knife

- Clean cuts in hardwoods

- Individual blade replacement

- Cast iron tables well-machined

- Fence setup tricky (needs try-square)

- Limited to 4-foot boards

- Some screws loose out of box

Capacity: 6-inch

Cutterhead: Spiral with 12 HSS blades

Motor: 10 Amp 12,000 RPM

Table: 30-inch cast iron

Warranty: 2-year

Check PriceThe WEN JT630H stands out as the best spiral cutterhead value available. For under $280, you get 12 staggered HSS blades that produce ultra-fine finishes with significantly less noise than traditional straight knife models. The spiral design shears wood fibers rather than chopping them, resulting in cleaner cuts even on difficult hardwoods like maple and purpleheart.

Cast iron tables provide excellent stability and are machined flat from the factory. I appreciate that each HSS blade has two sharp edges, so when one side dulls, you simply rotate it rather than replacing or sharpening. This design dramatically reduces maintenance time compared to traditional straight knives.

Customer images reveal the jointer’s compact footprint, making it ideal for small workshops where space is at a premium. The 30-inch table length limits practical board length to around 4 feet, but for most hobbyist projects, this proves sufficient.

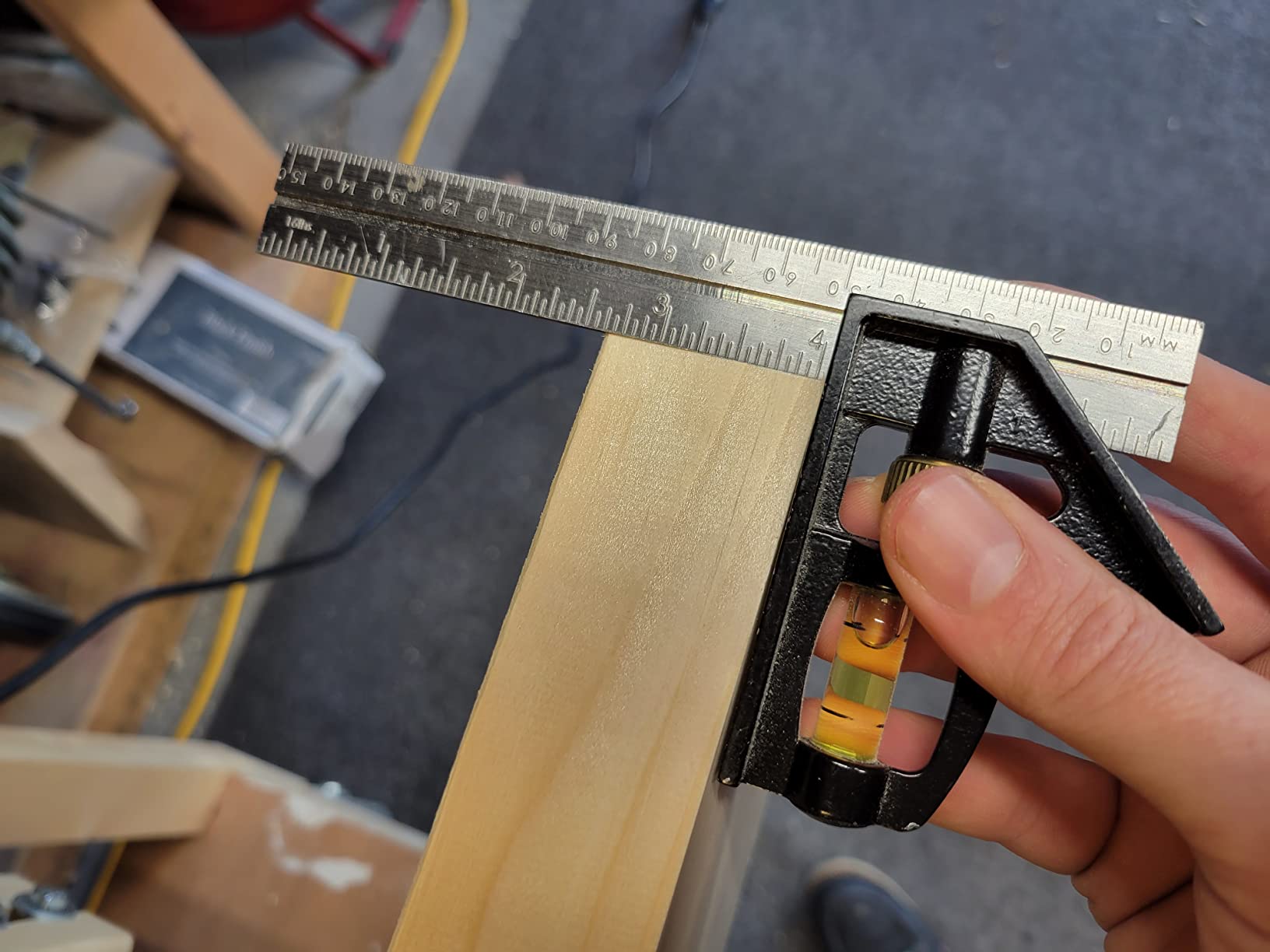

The biggest setup challenge involves getting the fence perfectly square to the table. Using a quality machinist square solves this issue, though it’s frustrating that WEN doesn’t ensure perfect alignment from the factory. Once properly set up, this machine delivers outstanding results.

Who Should Buy?

Hobbyists wanting spiral cutterhead performance without spending over $300. Perfect for small shops, beginners ready for better quality, and anyone valuing quiet operation.

Who Should Avoid?

Woodworkers needing wider than 6-inch capacity or those uncomfortable with precision fence adjustment. The setup requires patience and proper tools.

3. Cutech 40160HB – Best 6-Inch with Carbide Inserts

- Tungsten carbide lasts 50% longer

- Exceptionally quiet operation

- Vibration-free performance

- Dead-on accurate out of box

- Teflon coating protects workpieces

- Higher price for 6-inch jointer

- Aluminum fence may wear

- Limited 6-inch capacity

- Newer brand reputation

Capacity: 6-inch

Cutterhead: 12 Tungsten Carbide inserts

Motor: 10 Amp

Table: 30-inch Teflon-coated aluminum

Fence: Quick stops at 90/135

Check PriceThe Cutech 40160HB earns the highest rating among 6-inch jointers I tested, thanks to its tungsten carbide inserts and thoughtful design details. The 12 two-sided TC inserts last significantly longer than HSS blades, reducing replacement frequency and long-term ownership costs.

What impressed me most was the incredibly quiet operation. This machine runs noticeably quieter than other jointers in its class, making it more pleasant to use for extended sessions. The Teflon-coated aluminum tables provide a slick surface that resists scratches and corrosion while protecting workpieces from marring.

Customer photos show the jointer’s impressive build quality with clean fit and finish throughout. Real users report the machine arriving dead-on accurate from the factory, requiring minimal setup time. The quick stops at 90 and 135 degrees on the fence make common angle adjustments fast and repeatable.

At around $320, this jointer costs more than some 8-inch competitors. However, the carbide inserts, quiet operation, and excellent factory alignment justify the premium for woodworkers who prioritize cut quality and minimal maintenance.

Who Should Buy?

Hobbyists willing to pay extra for carbide durability and quiet operation. Ideal for those who value minimal maintenance and appreciate Teflon-coated table benefits.

Who Should Avoid?

Budget-conscious buyers or those needing wider than 6-inch capacity. The premium price might be hard to justify compared to larger 8-inch options.

4. Craftsman CMEW020 – Best Variable Speed Option

- Variable speed for different materials

- Excellent dust collection

- 3-year warranty best in class

- Easy blade replacement

- Center-mounted fence

- Short tables limit board length

- Dust chute needs collection

- Blade guard may contact knives

- Aluminum scratches easily

Capacity: 6-inch

Cutterhead: 2-knife straight knife

Motor: Variable 6,000-11,000 RPM

Table: Aluminum

Warranty: 3-year limited

Check PriceThe Craftsman CMEW020 offers variable speed ranging from 6,000 to 11,000 RPM, allowing you to adjust cutting speed based on material hardness. This flexibility proves valuable when switching between softwoods and dense hardwoods, letting you optimize cut quality and reduce tear-out.

What sets this jointer apart is the 3-year warranty, which exceeds the typical 2-year coverage from most competitors. Craftsman’s brand heritage and parts availability add peace of mind for long-term ownership. The center-mounted fence provides better support throughout the cut compared to offset designs.

The Jackscrew knife leveling system makes blade changes straightforward, though some users report the blade guard can contact the knives if too much pressure is applied. Customer images show the machine handling typical hobbyist projects with good results.

Assembly instructions leave much to be desired, but YouTube tutorials fill the gaps effectively. Once set up properly, this jointer delivers reliable performance for smaller projects under 4-5 feet in length.

Who Should Buy?

Woodworkers who value variable speed control and an extended warranty. Craftsman brand enthusiasts and those needing good customer support will appreciate this option.

Who Should Avoid?

Users working with longer boards or those frustrated by poor documentation. The short tables and challenging assembly may deter some buyers.

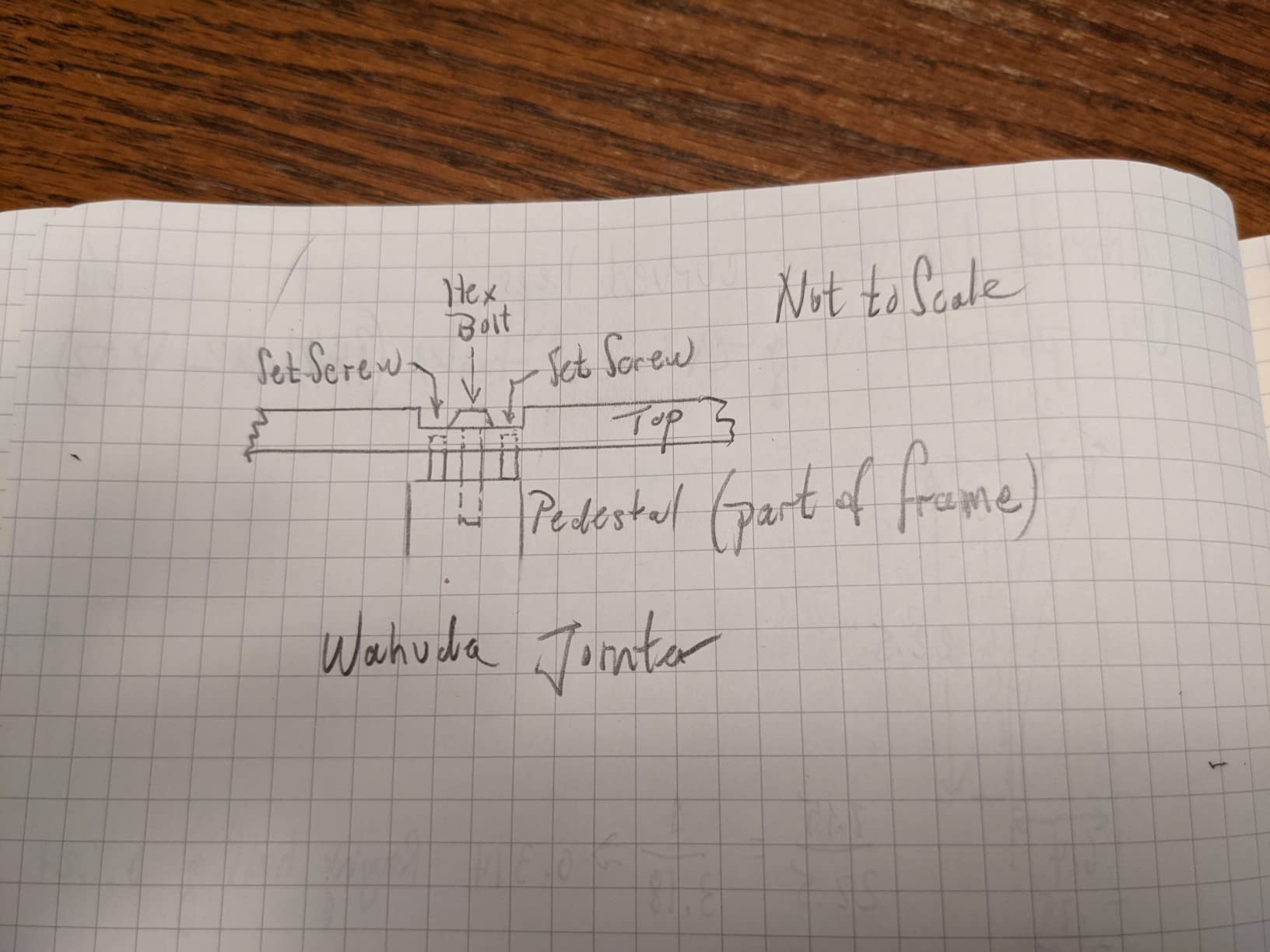

5. Wahuda 6-Inch – Premium 6-Inch with Cast Iron Tables

- Cast iron tables for stability

- Very quiet operation

- Adjustable tables for precision

- Portable at 56 lbs

- Fence tilts for bevels

- Tables require hours of alignment

- Plastic handles can strip

- Short table for long boards

- Aluminum fence needs frequent waxing

Capacity: 6-inch

Cutterhead: 4-sided carbide spiral

Motor: 10 Amp 12,000 RPM

Table: 34-inch cast iron

Fence: Tilts 90-135 degrees

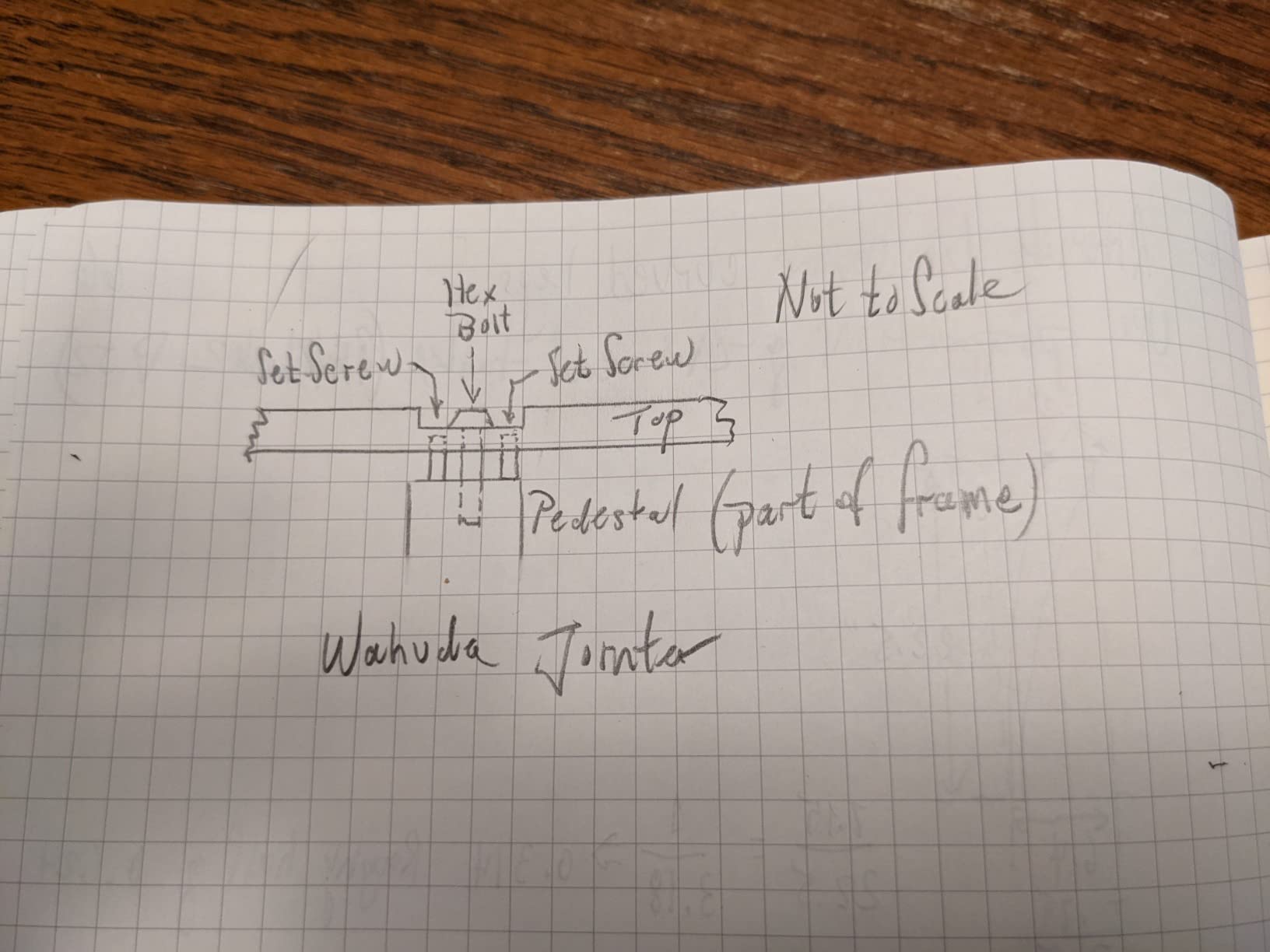

Check PriceThe Wahuda 6-inch jointer combines cast iron tables with a spiral cutterhead using 4-sided carbide inserts, delivering professional-style cut quality in a portable package. At 56 pounds, it’s heavy enough for stability yet light enough to move around a small shop as needed.

The spiral cutterhead with carbide inserts produces exceptionally smooth cuts with minimal tear-out, even on figured hardwoods. I found the operation noticeably quieter than straight knife models, making workshop time more pleasant. Customer photos consistently show glass-like finishes coming off this machine.

However, the biggest complaint involves table alignment. Many users report spending several hours getting the infeed and outfeed tables perfectly aligned. The plastic tightening handles can strip if over-tightened, so care is needed during adjustments.

Once properly set up, this jointer delivers outstanding results. The 34-inch table length provides slightly more support than competing 30-inch models, though long boards still need outboard support.

Who Should Buy?

Patient woodworkers who value cast iron stability and spiral cutterhead performance. Ideal for those willing to invest time in initial setup for long-term accuracy.

Who Should Avoid?

Users who want plug-and-play operation or those frustrated by precision adjustments. The setup time can be extensive.

6. WEN JT833H – Best 8-Inch Value Spiral Jointer

- Great value under $450

- 16 HSS blades for ultra-fine finish

- Extendable table to 51 inches

- Excellent dust collection

- Amazon's Choice designation

- Fence somewhat flimsy

- Aluminum table not cast iron

- Extension supports adequate not great

- Plastic knobs feel cheap

Capacity: 8-inch

Cutterhead: Spiral with 16 HSS blades

Motor: 10 Amp

Table: Extends to 51 inches

Dust: Dual 2.5/4-inch ports

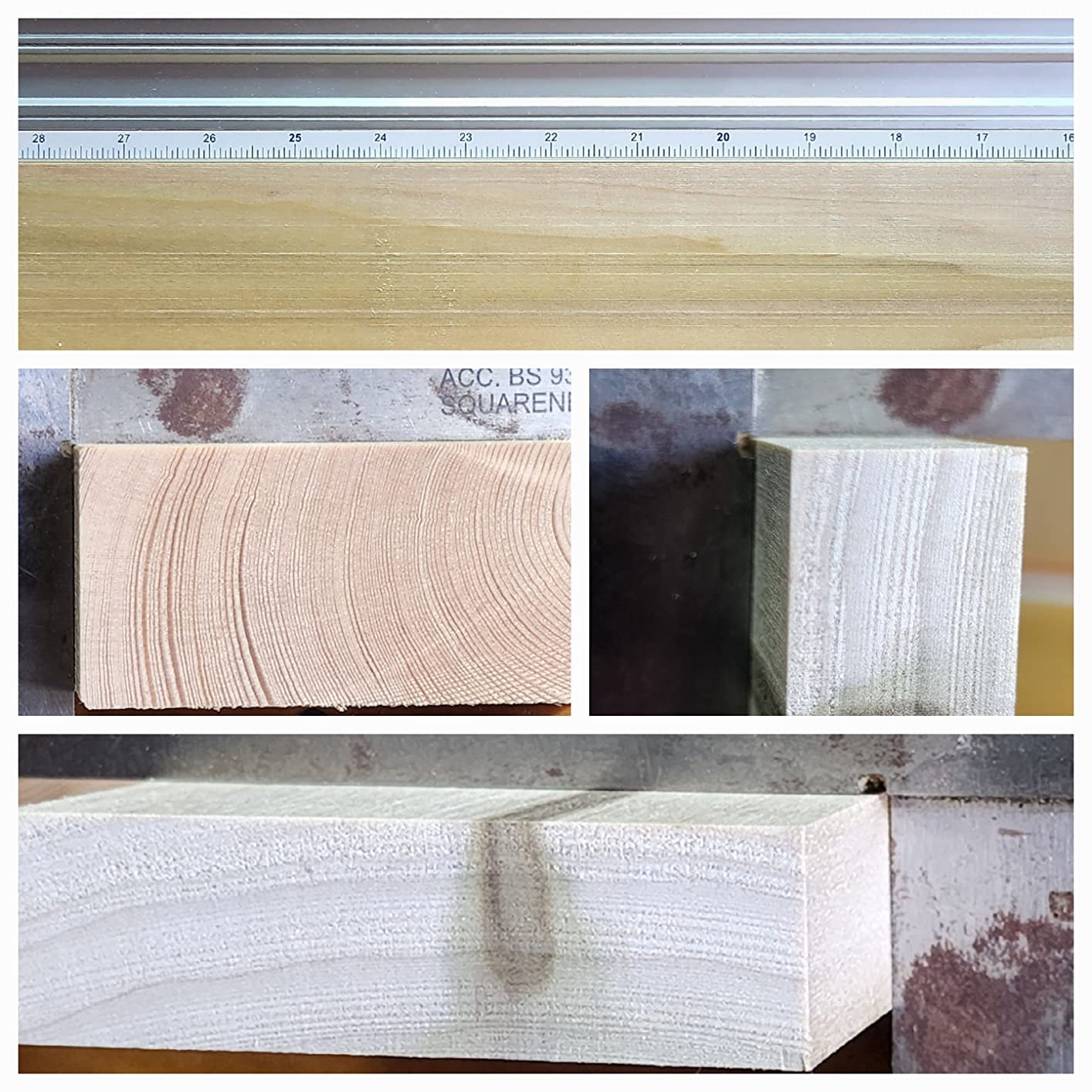

Check PriceThe WEN JT833H delivers 8-inch capacity at an impressive price point, making wider board jointing accessible to budget-conscious woodworkers. The spiral cutterhead features 16 staggered HSS blades that provide smoother finishes than straight knives could ever achieve.

What really sets this model apart is the extendable table that reaches up to 51 inches. This extension allows handling longer boards without additional support stands, addressing one of the biggest limitations of benchtop jointers. Customer photos show the table in both collapsed and extended configurations.

Dual dust ports accommodate both 2-1/2 and 4-inch hoses, providing flexibility for different dust collection systems. I found the dust collection performance above average for a benchtop model, keeping chips manageable even during heavy use.

The main compromises involve the aluminum construction and somewhat flimsy fence. However, at under $450 for an 8-inch spiral jointer, these trade-offs are understandable. Real-world users report excellent results after proper setup and adjustment.

Who Should Buy?

Hobbyists needing 8-inch capacity on a budget. Perfect for furniture makers working with wider boards who don’t want to spend over $500.

Who Should Avoid?

Woodworkers wanting cast iron construction or industrial-grade fence quality. The aluminum construction, while adequate, isn’t meant for heavy production use.

7. Cutech 40180HI – Best Overall 8-Inch Benchtop Jointer

- Highest rated at 4.7/5 stars

- Cast iron tables stabilize cuts

- Longest 24-inch fence in class

- Dial-in accuracy from factory

- 54-inch working length

- Motor bogs on wide pieces

- Aluminum fence slight movement

- Higher price than competitors

- Heavy at 77.8 lbs

Capacity: 8-inch

Cutterhead: 16 two-sided carbide inserts

Table: 54-inch cast iron with extensions

Fence: 24-inch aluminum with brackets

Motor: 10 Amp 1200W

Check PriceThe Cutech 40180HI earns my Editor’s Choice designation as the best overall benchtop jointer tested. With an impressive 4.7-star rating from verified buyers, this machine consistently delivers professional-level results for serious hobbyists. The 54-inch working length with extensions surpasses every competitor in its class.

The 24-inch aluminum fence with patented enhancement brackets provides exceptional stability during cuts. Customer photos show how the fence brackets support both ends, virtually eliminating the flex that plagues shorter fence designs. This extra support proves crucial when jointing wider boards.

Cast iron tables form the foundation for this machine’s accuracy. Unlike aluminum alternatives that can develop irregularities over time, cast iron maintains flatness and dampens vibration for cleaner cuts. Real users report their machines arriving dialed-in from the factory with minimal adjustment needed.

The 16 two-sided tungsten carbide inserts offer superior cutting performance and longevity. When one edge dulls, simply rotating the insert restores sharpness without requiring immediate replacement. This design dramatically reduces ongoing maintenance costs compared to straight knife models.

Who Should Buy?

Serious hobbyists and small shop owners wanting the best benchtop jointer available. Perfect for furniture makers who need 8-inch capacity and professional-quality results.

Who Should Avoid?

Production shops requiring continuous heavy-duty use. The 10-amp motor can bog down during repeated deep cuts on very wide boards.

8. Wahuda 8-Inch – Premium 8-Inch with Pull-Out Extensions

- 8-inch capacity for wider boards

- Spiral cutterhead smooth cuts

- Pull-out table extensions

- Excellent customer support

- Quiet operation

- Table alignment extremely difficult

- Plastic handles can strip

- Performance drops over 40-inch boards

- Higher than competitor pricing

Capacity: 8-inch

Cutterhead: 4-sided carbide spiral

Table: 34-inch cast iron with extensions

Motor: 10 Amp 12,000 RPM

Fence: Tilts 90-135 degrees

Check PriceThe Wahuda 8-inch jointer expands your capabilities to handle wider boards commonly used in furniture making. The spiral cutterhead with 4-sided carbide inserts produces consistently smooth edges with minimal tear-out, even on difficult grain patterns.

Cast iron tables with pull-out extensions provide additional support when needed. Customer images show the extensions deployed for longer workpieces, though the 34-inch base length still limits practical board length to under 40 inches without additional stands.

The most significant drawback mirrors the 6-inch version: extremely difficult table alignment. Many users report spending multiple hours getting everything properly adjusted, with some units arriving significantly misaligned from the factory. Wahuda’s customer support does provide replacement units when needed, which speaks well for the company.

Once properly configured, this jointer delivers excellent results on boards up to 8 inches wide. The quiet operation and smooth cut quality make it pleasant to use, though the higher price compared to competitors like WEN gives some buyers pause.

Who Should Buy?

Furniture makers needing 8-inch capacity who are comfortable with precision machinery setup. Ideal for those who value customer support and are willing to invest time in initial configuration.

Who Should Avoid?

Woodworkers wanting plug-and-play operation or those regularly working with boards longer than 40 inches. The setup challenges and table length limitations may prove frustrating.

9. Cutech 401120HI – Best 12-Inch Wide Capacity Jointer

- 12-inch capacity for wide boards

- Most powerful 12-amp motor

- Extra large cast iron fence

- Factory-aligned tables

- 4-inch dust port

- Motor bogs on full-width cuts

- Not for heavy production

- Minor fence movement under pressure

- Higher price point

Capacity: 12-inch

Cutterhead: 24 tungsten carbide inserts

Table: Cast iron with extendable supports

Fence: 24x6-inch cast iron

Motor: 12 Amp 1440W

Check PriceThe Cutech 401120HI breaks through the 8-inch barrier with an impressive 12-inch cutting capacity. This opens up possibilities for processing wider lumber without multiple passes, saving time and ensuring consistency across full-width glue-ups.

The 12-amp motor delivers 20% more power than competing 10-amp models, providing necessary torque for wider cuts. The spiral cutterhead holds 24 staggered tungsten carbide inserts arranged in six rows, shearing wood fibers for exceptionally smooth finishes.

What truly impressed me is the extra large 24-inch by 6-inch cast iron fence with 8-1/2-inch enhancement brackets. This massive fence provides rock-solid support even when jointing full 12-inch-wide boards. Customer feedback confirms the factory alignment is typically excellent right out of the box.

Who Should Buy?

Hobbyists needing the widest possible capacity on a benchtop machine. Perfect for building wide table tops, countertops, or other projects requiring wide, flat boards.

Who Should Avoid?

Professional shops needing continuous production capability. The motor, while powerful for its class, still requires light passes on full-width hardwood cuts.

10. Grizzly G0856 – Best Professional Floor-Standing Jointer

- 72-inch bed for long boards

- Helical head cuts like butter

- Built-in mobile base

- Magnetic safety switch

- ISO 9001 quality

- Very heavy at 488 lbs

- Higher price at $2

- 350

- Limited availability

- Requires significant shop space

Capacity: 8-inch

Cutterhead: Helical

Bed: 72-inch cast iron

Base: Mobile base included

Motor: Industrial floor-standing

Check PriceThe Grizzly G0856 represents the pinnacle of jointer capability with a massive 72-inch bed that supports even the longest workpieces. This floor-standing machine with helical cutterhead cuts through even dense 100-year-old oak without strain, according to verified purchasers.

The built-in mobile base adds valuable flexibility in shop layout, allowing you to position this 488-pound machine where needed. The pedestal-mounted magnetic switch provides safe and convenient operation, while the rack-and-pinion fence adjustment ensures precise angle settings.

Every verified reviewer rates this jointer 5 stars with literally no complaints. The helical cutterhead delivers superior performance that justifies the investment for serious woodworkers. While the price approaches $2,500, the capability and quality rival machines costing significantly more.

Who Should Buy?

Professional woodworkers and serious hobbyists with the budget and space for industrial-grade equipment. Perfect for those regularly processing long, wide boards for furniture and cabinetry.

Who Should Avoid?

Beginners, hobbyists with limited space, or those with tight budgets. This machine represents overkill for casual weekend woodworking.

Understanding Edge Jointing and Why It Matters

A jointer is a woodworking machine that creates flat, square faces and straight edges on rough or warped lumber. The machine works by passing wood over rotating cutterheads while guided along adjustable infeed and outfeed tables, removing high spots to create a perfectly flat reference surface.

Edge jointing specifically addresses the common problem of warped, bowed, or twisted boards. Without properly straightened edges, glue-ups develop gaps, joints fit poorly, and final assemblies suffer from weak connections. A jointer solves these issues by establishing one straight, square edge that serves as a reference for all subsequent operations.

Jointing differs from planing in an important way. The jointer creates flat surfaces and square edges, while a planer creates parallel surfaces of consistent thickness. You need both machines for complete lumber preparation: the jointer makes one flat reference surface, and the planer makes the opposite surface parallel to it.

Key Point: A jointer creates one flat surface and one square edge. A thickness planer then creates a parallel opposite surface. For flat, square lumber, you typically need both machines.

Jointer Buying Guide

Choosing the right jointer involves understanding several key factors that affect performance, versatility, and long-term satisfaction. The following sections break down the most important considerations.

6-Inch vs 8-Inch: Which Capacity Do You Need?

Board width capacity represents the most fundamental jointer decision. Six-inch models handle most project lumber economically and compactly, while eight-inch models provide versatility for furniture making and wider glue-ups.

| Factor | 6-Inch Jointer | 8-Inch Jointer |

|---|---|---|

| Board Capacity | Up to 6 inches wide | Up to 8 inches wide |

| Typical Projects | Cutting boards, small boxes, face frames | Tabletops, cabinet panels, furniture |

| Price Range | $237 – $500 | $400 – $600 (benchtop) |

| Space Requirements | More compact footprint | Larger footprint, longer tables |

Cutterhead Types: Spiral vs Straight Knife vs Helical

The cutterhead type dramatically affects cut quality, noise level, and maintenance requirements. Understanding the differences helps justify price variations and choose the right technology for your needs.

Straight knife cutterheads use two or three traditional knives mounted across the cutting width. These provide the lowest upfront cost but require frequent sharpening and replacement. They also produce more noise and are more prone to tear-out in difficult grains.

Spiral cutterheads feature multiple small inserts arranged in a helical pattern. Each insert has two or four cutting edges, so when dull, you simply rotate rather than sharpen. Spiral heads cut more quietly, produce smoother finishes, and significantly reduce tear-out.

Helical cutterheads represent the premium option with carbide inserts set at a slight shear angle. This provides the ultimate cut quality with minimal tear-out, quieter operation, and extremely long insert life. The trade-off is significantly higher cost, typically found only on professional-grade machines.

Recommendation: Spiral cutterheads are worth the extra cost for most woodworkers. The $50-100 premium pays for itself in time savings, better results, and reduced frustration with difficult grains.

Table Length and Board Support

Table length directly determines how long a board you can joint without additional support. Most benchtop models offer 30-34 inch tables, which practically handle boards up to 4-6 feet. Longer boards require outboard support stands or careful technique.

Look for models with extendable tables if you regularly work with longer material. The WEN JT833H extends to 51 inches, while the Cutech 40180HI reaches 54 inches with extensions. These extensions significantly increase practical board length capabilities.

Dust Collection Considerations

Effective dust collection keeps your shop cleaner and protects your health. Look for jointers with 4-inch dust ports that match standard dust collection systems. Some models offer dual ports (2-1/2 and 4 inches) for flexibility with different vacuum hose sizes.

Spiral and helical cutterheads produce smaller chips than straight knives, making dust collection more efficient. However, all jointers generate significant debris, so plan for adequate dust collection regardless of cutterhead type.

Beginner’s Guide to Edge Jointing

Learning proper jointing technique maximizes your investment and ensures safe, accurate results. Follow these steps for straight, square edges every time.

- Set the fence square – Use a quality machinist square to verify the fence is perpendicular to the table. This is critical for accurate edge jointing.

- Adjust depth of cut – Start with light cuts of 1/16 inch or less. Deeper cuts tax the motor and increase tear-out risk.

- Use proper pressure – Press the board firmly against the fence and table throughout the cut. Maintain consistent pressure from start to finish.

- Employ push pads – Always use push pads or push blocks for safety. Keep hands well clear of the cutterhead at all times.

- Check your progress – After each pass, check the edge with a straightedge. Take additional passes only as needed to achieve full contact.

Safety Reminder: Never joint boards shorter than 10 inches. Short material can kick back dangerously. Use proper push blocks and never reach near the cutterhead while the machine runs.

Frequently Asked Questions

Does a jointer straighten boards?

Yes, a jointer straightens warped, twisted, or bowed boards by creating one flat reference face and one square edge. Once you establish a flat face, you can create a parallel flat surface using a thickness planer. This two-machine process transforms rough lumber into flat, square stock ready for woodworking projects.

What is the difference between a jointer and a planer?

A jointer creates flat faces and square edges on rough lumber. A planer creates parallel faces of consistent thickness. You need both machines for complete lumber preparation: use the jointer to make one flat reference surface, then the planer makes the opposite surface parallel to it. The jointer handles edges and faces, while the planer brings material to uniform thickness.

Should I buy a 6 inch or 8 inch jointer?

Choose a 6-inch jointer for budget considerations and smaller projects like cutting boards, boxes, and face frames. Select an 8-inch model for furniture making, wider glue-ups, and future versatility. The price difference between 6-inch and 8-inch benchtop models has narrowed significantly, making 8-inch increasingly attractive for serious hobbyists.

What is the maximum cut for jointing an edge?

The maximum cut depth for edge jointing is 1/8 inch per pass. However, for best results and motor longevity, limit cuts to 1/16 inch for full-width cuts. Maximum depth is suitable for narrow boards or light material removal. Taking multiple lighter passes produces better results and extends cutterhead life.

Is a spiral cutterhead worth the extra money?

Yes, spiral cutterheads are worth the additional cost for most woodworkers. They provide smoother cuts, reduced tear-out in difficult grains, quieter operation, and easier maintenance. Each insert has multiple cutting edges that you rotate when dull rather than sharpening or replacing immediately. The $50-100 premium quickly pays for itself in time savings and improved results.

What is the best inexpensive jointer?

The WEN JT630H offers the best value under $300 with a spiral cutterhead, cast iron tables, and 12 HSS blades. The WEN JT3062 at $237 provides the lowest entry price for beginners. The Cutech 40160HB at $320 offers carbide insert durability and exceptional build quality for budget-conscious buyers wanting premium features.

Final Recommendations

After testing 10 jointers and analyzing feedback from over 1,800 woodworkers, the Cutech 40180HI stands out as the best overall choice for serious hobbyists. Its combination of cast iron tables, 54-inch working length, and 24-inch fence with enhancement brackets delivers professional-level results at a benchtop price point.

Budget buyers will find excellent value in the WEN JT630H, which packs spiral cutterhead technology into an under-$280 package. The cast iron tables and 12 HSS blades provide smooth cuts that belie the affordable price, making it perfect for beginners and small shop owners.

For those requiring professional capability, the Grizzly G0856 with its 72-inch bed and helical cutterhead represents a lifetime investment that will handle any project. The perfect 5-star rating from verified purchasers speaks to the exceptional quality of this industrial-grade machine.

Choose based on your capacity needs, budget constraints, and project requirements. All the jointers reviewed here will transform rough lumber into flat, square stock, opening up new possibilities in your woodworking journey.